Get Professional Backup Generator Maintenance

in Seattle, Everett, Kirkland, Marysville, Redmond,

Edmonds, Bellevue, Snohomish, Shoreline,

Bothell, Mercer Island, Woodinville or Cottage Lake, Washington

Ready for a licensed electrician to help you with professional backup

generator maintenance and backup power system service in

Seattle, Everett, Kirkland, Marysville, Redmond, Edmonds,

Bellevue , Snohomish, Shoreline, Bothell, Mercer Island, Woodinville or Cottage Lake?

Call us at (425)552-1502 or fill out the form below so we can schedule your appointment.

Schedule Appointment

Expert Backup Generator Maintenance for Reliable Backup Power Systems Throughout Western Washington

Neglected backup generator maintenance represents one of the most common reasons backup power systems fail during emergencies, with poorly maintained backup generators experiencing startup failures, fuel system problems, battery issues, and electrical malfunctions precisely when homeowners need backup power most during storms and power outages. Whether you own a whole-house backup generator requiring annual professional backup service, a portable backup generator needing seasonal maintenance before storm season, a commercial backup power system demanding scheduled preventive backup care, or an aging backup generator showing signs of wear that requires comprehensive backup inspection and repair, JCS Electrical delivers the comprehensive electrical expertise that has earned us five-star Google reviews and the trust of more than 100 property owners throughout Snohomish and King Counties.

Call (425) 552-1502 for professional water heater wiring anywhere in our service area.

When Your Backup Generator Needs Professional Maintenance Service

Identifying the need for professional backup generator maintenance often becomes apparent when backup power systems fail to start during outages or show backup performance problems during testing, but there are clear indicators that suggest your backup generator would benefit significantly from preventive backup service before emergencies occur. Existing backup generators in many homes receive inadequate attention between installations and failures, especially standby backup systems that run infrequently making regular professional assessment and backup maintenance essential for reliable backup power.

Critical backup maintenance needs make professional backup generator service essential including annual standby backup generator inspections that verify backup operational readiness and identify developing backup problems, seasonal portable backup generator service that ensures reliable backup starting and safe backup operation before storm season arrives, post-outage backup inspections following extended backup generator operation that may reveal wear or developing backup issues, and aging backup generator assessments that determine whether backup repairs or replacement provide better value for backup power reliability.

The reliability impact of neglected backup generator maintenance becomes obvious when considering potential consequences including backup startup failures when backup generators won't start during power outages leaving families without backup power, backup fuel system problems from stale gasoline or contaminated diesel that prevent proper backup engine operation, backup battery failures that disable electric start systems and automatic backup transfer switch activation, and backup electrical issues that cause backup generators to shut down unexpectedly or fail to deliver proper backup power output.

Many property owners assume backup generators will work when needed without regular backup service, but backup power systems require specific backup maintenance including oil changes and filter replacements that keep backup engines running reliably, backup fuel system service that prevents carburetor problems and fuel degradation issues, backup battery testing and replacement that ensures reliable electric starting and automatic backup operation, and backup electrical system inspection that verifies proper output voltage and backup transfer switch function.

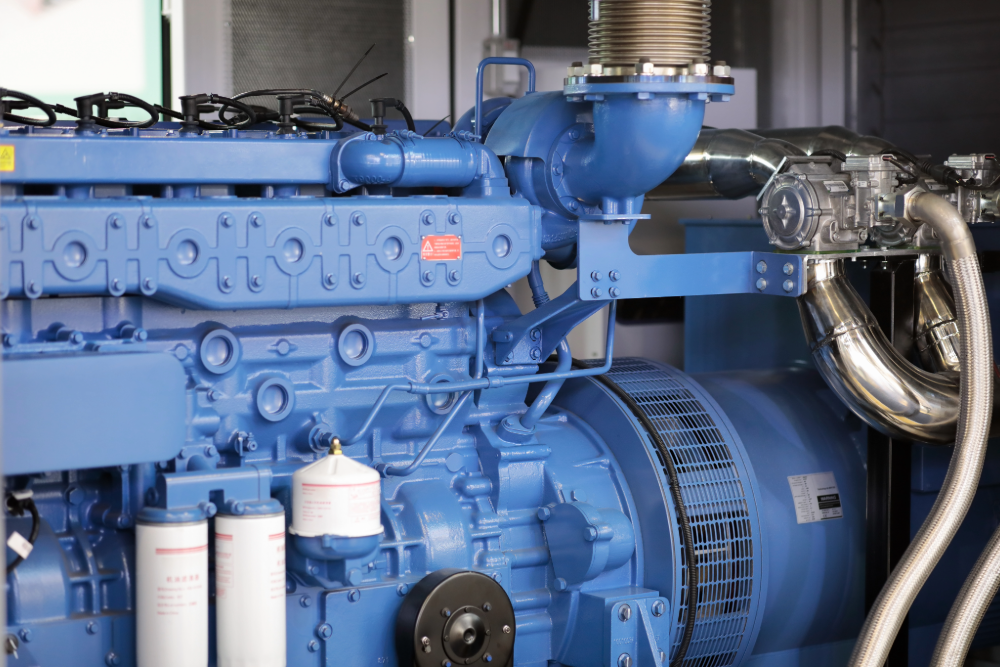

Understanding Backup Generator Maintenance Requirements

Modern backup generators represent significant investments in emergency preparedness, providing backup electricity through complex mechanical and electrical backup systems that require regular professional attention to maintain backup reliability. These backup power systems operate under demanding conditions and need scheduled backup maintenance to ensure they perform when utility power fails and backup power is needed.

Skipped backup maintenance creates reliability and safety problems but may seem unnecessary during normal utility operation, allows small backup issues to develop into major backup failures requiring expensive repairs, permits backup fuel system degradation that causes hard starting and poor backup performance, and enables backup electrical problems that may create safety hazards or damage connected equipment during backup operation.

Backup generator maintenance requirements depend on your specific backup equipment type and usage patterns including standby backup generators that require annual professional backup service plus regular exercise cycles to maintain backup readiness, portable backup generators that need seasonal backup service before storm season and proper storage preparation for off-season periods, commercial backup generators that demand scheduled backup maintenance intervals based on runtime hours and manufacturer specifications, and dual-fuel backup generators that require attention to both gasoline and propane backup fuel system components.

Our Comprehensive Backup Generator Maintenance Strategy

Effective backup generator maintenance requires systematic backup inspection and service procedures that ensure reliable backup operation throughout your backup power system. Our approach begins with comprehensive backup generator assessment including review of backup equipment specifications, maintenance history, and manufacturer backup service requirements, evaluation of current backup generator condition including engine, fuel system, electrical output, and backup control systems, assessment of operating environment and usage patterns that affect backup maintenance intervals and service needs, and development of backup maintenance plans that provide reliable backup generator operation within manufacturer guidelines and industry best practices.

The backup maintenance process involves implementing manufacturer-recommended backup service procedures that maintain warranty coverage and ensure reliable backup operation, while inspecting backup electrical connections, testing backup output voltage, and verifying backup transfer switch function through systematic methods that ensure safe backup operation and identify developing backup problems before they cause failures.

We use only high-quality replacement parts throughout the backup maintenance process including manufacturer-specified oil and filters that provide proper backup engine protection and performance, quality backup fuel system components that ensure reliable fuel delivery and prevent contamination issues, appropriate backup batteries that provide adequate cranking power for reliable backup starting, and proper backup electrical components that maintain safe, reliable backup power output and control system function.

We understand that backup generator systems involve complex mechanical and electrical backup components that many property owners find technical, so we provide clear explanations of backup maintenance findings and recommendations to help you make informed decisions about your backup power investment.

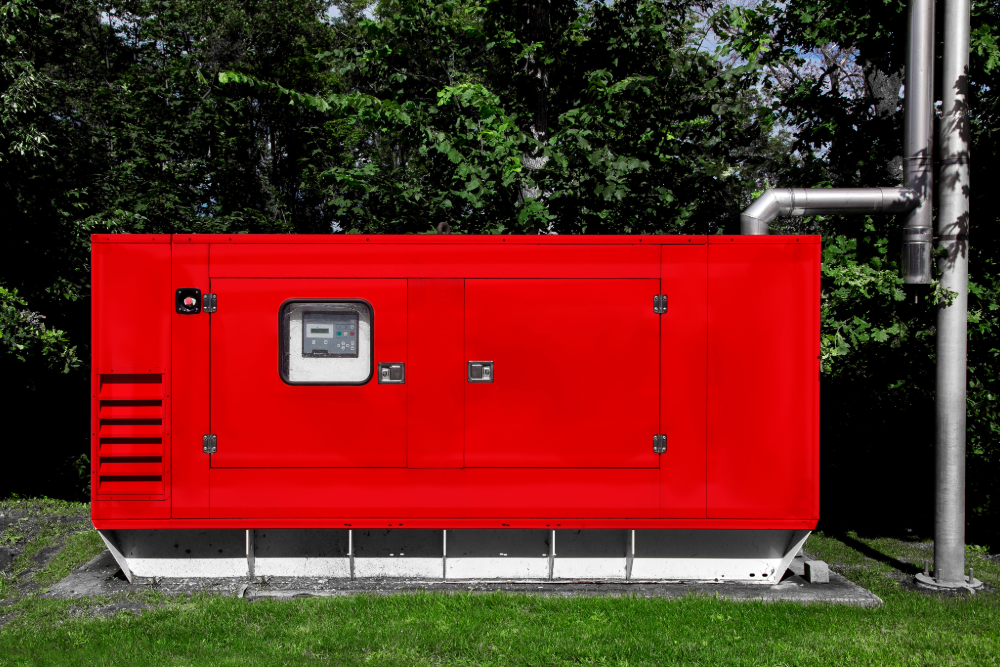

Standby Backup Generator Maintenance Services

Standby backup generators require comprehensive annual backup maintenance that ensures automatic backup operation when utility power fails. These whole-house backup systems represent significant investments that protect families and property during extended outages, making professional backup service essential for reliable backup performance.

Standby backup generator maintenance includes backup engine service encompassing oil changes, filter replacements, and spark plug inspection that maintain reliable backup operation, backup fuel system inspection that verifies proper fuel delivery, regulator function, and leak-free connections for backup power, backup battery testing that confirms adequate charge and cranking capacity for reliable automatic backup starting, backup electrical system inspection that verifies proper output voltage, frequency, and backup transfer switch operation, and backup control system testing that confirms automatic backup start sequences, exercise schedules, and fault monitoring function properly.

Professional standby backup maintenance ensures these backup systems operate effectively including Generac backup generator service following manufacturer protocols for Guardian, Protector, and commercial series backup units, Kohler backup generator maintenance addressing specific requirements for residential and commercial standby backup systems, Briggs & Stratton backup generator service maintaining proper operation of home standby backup units, and Cummins backup generator maintenance for residential and light commercial backup power systems.

Standby backup generator maintenance provides particular value for properties with specific backup needs like homes dependent on backup power for medical equipment, sump pumps, or well systems, properties in areas experiencing frequent or extended utility outages requiring reliable backup, homes with significant investments in refrigerated or frozen food storage requiring uninterrupted backup power, and families with vulnerable members who cannot tolerate extended periods without heating or cooling and need dependable backup.

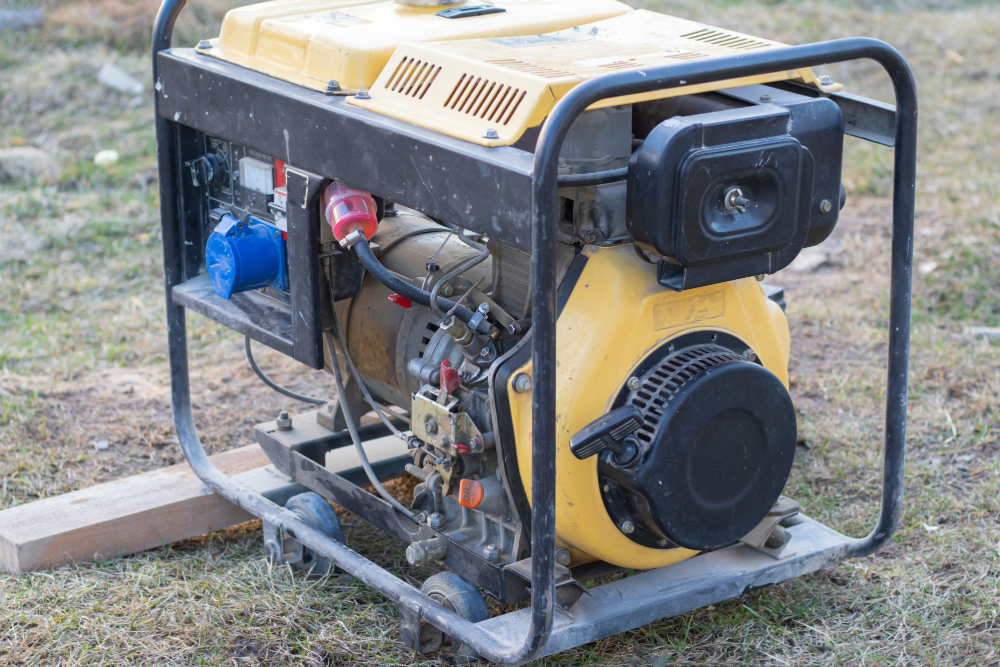

Portable Backup Generator Maintenance Services

Portable backup generators require seasonal backup maintenance that ensures reliable backup starting and safe backup operation when backup power is needed. These versatile backup units often sit unused for extended periods, making proper backup service and storage preparation essential for dependable emergency backup performance.

Portable backup generator maintenance includes backup engine service encompassing oil changes, air filter cleaning or replacement, and spark plug inspection, backup fuel system service including carburetor cleaning, fuel line inspection, and fuel stabilizer treatment, backup starting system inspection verifying pull cord condition, electric start function, and backup battery charge, backup output testing confirming proper voltage and frequency under load conditions, and backup safety system verification ensuring proper ground fault protection and overload shutdown function.

Seasonal backup maintenance timing ensures reliable backup operation including pre-storm season backup service that verifies backup operational readiness before winter weather arrives, post-season backup service that prepares backup generators for storage with proper fuel treatment and protection, post-outage backup inspection following extended backup operation that identifies wear or developing backup problems, and annual comprehensive backup service that addresses all backup maintenance requirements regardless of usage patterns.

Portable backup generator maintenance provides benefits including reliable backup starting when backup power is needed during emergencies, extended backup equipment lifespan through proper care and timely component replacement, safe backup operation through verified electrical output and properly functioning backup safety systems, and reduced backup repair costs by addressing minor backup issues before they cause major failures.

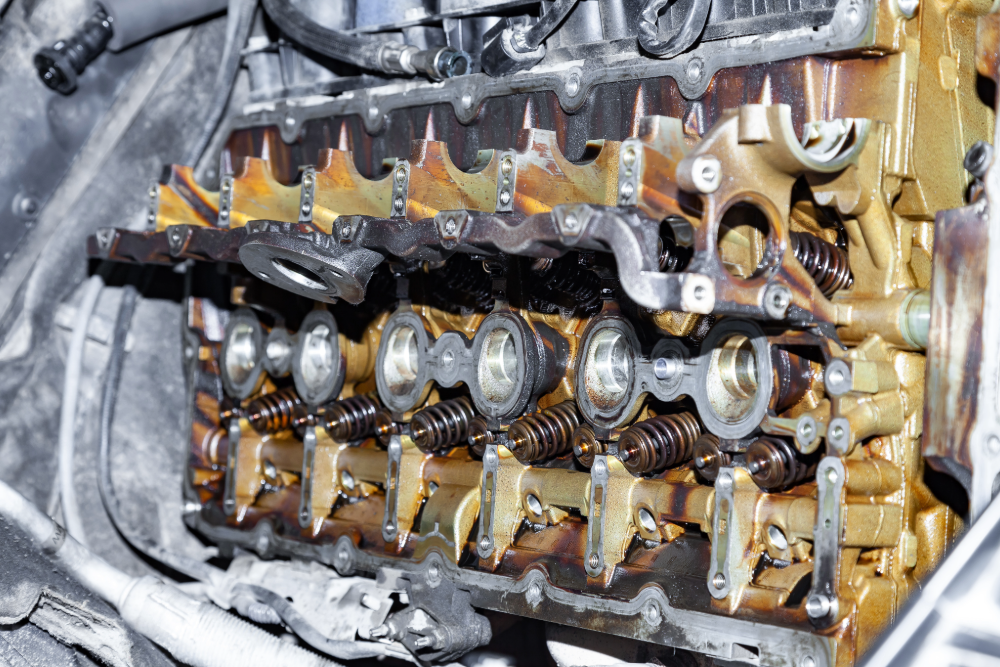

Backup Generator Oil Change and Engine Service

Regular oil changes represent the most critical backup maintenance requirement for backup generator engines, providing essential lubrication that prevents wear and extends backup equipment lifespan. Proper backup engine service maintains reliable backup operation and prevents costly backup failures.

Backup oil change requirements include manufacturer-specified oil types that provide proper viscosity and protection for backup generator engines, appropriate change intervals based on backup runtime hours or calendar time whichever occurs first, oil filter replacement that removes contaminants and maintains proper oil flow in backup systems, and used oil disposal following environmental regulations and proper handling procedures.

Additional backup engine service includes air filter inspection and replacement that ensures proper air flow for efficient backup combustion, spark plug inspection and replacement that maintains reliable backup ignition and efficient operation, backup cooling system inspection that verifies proper airflow and prevents overheating damage, and backup exhaust system inspection that identifies leaks or restrictions affecting backup performance and safety.

Our backup engine service expertise ensures backup generator engines receive proper care that maintains reliable backup operation while extending backup equipment lifespan and preventing premature backup failures.

Backup Generator Fuel System Service and Maintenance

Backup fuel system problems represent the leading cause of backup generator failures, with stale gasoline, contaminated fuel, and carburetor issues preventing reliable backup starting and operation. Professional backup fuel system service prevents these common backup problems and ensures dependable backup power.

Gasoline backup fuel system service includes carburetor inspection and cleaning that removes deposits and ensures proper fuel metering for backup operation, backup fuel line inspection that identifies cracks, deterioration, or connection leaks, backup fuel filter replacement that prevents contamination from reaching carburetor components, backup fuel tank inspection that identifies rust, contamination, or vent problems, and fuel stabilizer treatment that prevents gasoline degradation during backup storage periods.

Propane and natural gas backup fuel system service includes backup regulator inspection that verifies proper pressure reduction and fuel delivery, backup gas line inspection that identifies leaks or connection problems, backup solenoid valve testing that confirms proper fuel shutoff and flow control, and backup fuel pressure verification that ensures adequate supply for proper backup generator operation.

Our backup fuel system expertise addresses the most common backup generator reliability issues while ensuring proper fuel delivery for dependable backup power operation.

Backup Generator Battery Testing and Replacement

Backup generator batteries provide essential starting power for electric start backup systems and enable automatic operation of standby backup generators. Backup battery failures represent a common cause of backup generator problems that can be prevented through regular backup testing and timely replacement.

Backup battery service includes load testing that verifies adequate cranking capacity under realistic backup starting conditions, voltage testing that confirms proper charge and backup charging system function, terminal inspection that identifies corrosion or loose connections affecting backup performance, electrolyte level checking for serviceable backup batteries requiring periodic water addition, and backup battery replacement when testing indicates inadequate capacity or approaching end of service life.

Backup battery maintenance considerations include proper backup battery sizing that provides adequate cranking amps for reliable backup starting in cold weather, appropriate backup battery types matching generator manufacturer specifications and backup charging systems, backup charging system verification that ensures batteries maintain proper charge between backup uses, and environmental factors that affect backup battery lifespan including temperature extremes and vibration exposure.

Our backup battery service expertise ensures backup generators start reliably when needed while preventing unexpected backup failures that leave properties without backup power during outages.

Backup Generator Electrical System Inspection and Testing

Backup generator electrical systems produce and regulate backup power output, making proper function essential for safe, effective backup power operation. Professional backup electrical inspection verifies backup generators deliver proper voltage and frequency while protecting connected equipment during backup operation.

Backup electrical system inspection includes backup output voltage testing that verifies proper 120-volt and 240-volt production under load, backup frequency verification that confirms proper 60Hz output for safe equipment operation, backup voltage regulation testing that ensures stable output despite changing loads, backup ground fault circuit interrupter testing that verifies proper shock protection function, and backup wiring inspection that identifies loose connections, corrosion, or damage affecting backup performance.

Backup transfer switch inspection includes automatic backup transfer switch testing that verifies proper utility sensing and backup transfer operation, manual backup transfer switch inspection that confirms proper operation and interlock function, backup transfer timing verification that ensures appropriate delay for utility stabilization, and backup connection inspection that identifies loose or corroded terminals affecting backup reliability.

Our backup electrical system expertise ensures backup generators produce safe, properly regulated backup power while backup transfer systems operate correctly for seamless backup power activation.

Backup Generator Exercise and Testing Programs

Regular backup generator exercise maintains backup operational readiness by circulating oil, charging backup batteries, and verifying backup system function between actual power outages. Proper backup exercise programs prevent reliability problems that develop during extended backup idle periods.

Backup exercise program benefits include oil circulation that maintains lubrication throughout backup engine components during idle periods, backup battery charging that maintains adequate charge for reliable backup starting, backup fuel system function that prevents carburetor varnish and fuel line deterioration, and backup problem identification that reveals developing backup issues during controlled testing rather than emergency backup operation.

Backup exercise program recommendations include weekly automatic exercise for standby backup generators running 15-20 minutes under load, monthly manual exercise for portable backup generators running under load until fully warmed, backup load testing during exercise that verifies proper backup performance under realistic power demands, and backup exercise documentation that tracks backup generator operation and identifies backup performance trends.

Our backup exercise program expertise helps property owners establish proper backup testing schedules that maintain backup generator readiness while identifying backup problems before emergency situations occur.

Backup Generator Cooling System Maintenance

Backup generator cooling systems prevent overheating that causes backup engine damage and premature backup failure. Proper backup cooling system maintenance ensures backup generators can operate continuously during extended outages without thermal problems affecting backup performance.

Air-cooled backup generator maintenance includes backup cooling fin inspection and cleaning that ensures proper heat dissipation, backup air intake and exhaust inspection that verifies unobstructed airflow, backup fan and shroud inspection that confirms proper air circulation around backup engine components, and operating environment assessment that identifies factors affecting backup cooling effectiveness.

Liquid-cooled backup generator maintenance includes backup coolant level and condition inspection that verifies proper freeze and corrosion protection, backup radiator inspection that identifies leaks, blockages, or damage affecting backup cooling capacity, backup hose inspection that reveals deterioration, cracks, or connection problems, backup thermostat testing that confirms proper temperature regulation, and backup water pump inspection that verifies adequate coolant circulation.

Our backup cooling system expertise ensures backup generators maintain proper operating temperatures for reliable, extended backup operation during power outages.

Backup Generator Enclosure and Environmental Protection

Backup generator enclosures protect backup equipment from weather, debris, and environmental damage while ensuring proper ventilation for safe backup operation. Backup enclosure maintenance preserves backup generator condition and prevents problems caused by moisture, pests, and contamination.

Backup enclosure maintenance includes exterior inspection that identifies rust, damage, or deterioration requiring attention, backup ventilation verification that ensures adequate airflow for cooling and exhaust evacuation, backup seal and gasket inspection that confirms weather protection around doors and access panels, backup pest inspection that identifies rodent or insect intrusion causing wiring damage or blockages, and backup drain verification that ensures condensation and rainwater exit properly without pooling.

Environmental considerations for backup systems include debris clearance that maintains proper clearance around backup enclosures for ventilation and service access, vegetation management that prevents plant growth from blocking airflow or creating fire hazards near backup equipment, snow and ice management that ensures backup generators remain accessible and properly ventilated during winter, and drainage assessment that prevents water accumulation around backup generator installations.

Our backup enclosure maintenance expertise ensures backup generators remain protected from environmental damage while maintaining proper operating conditions for reliable backup power.

Backup Generator Maintenance Schedules and Service Intervals

Proper backup maintenance scheduling ensures backup generators receive timely service that prevents backup problems while maintaining manufacturer warranty coverage. Backup service intervals vary based on backup generator type, usage patterns, and manufacturer specifications.

Standby backup generator maintenance intervals include weekly automatic exercise that maintains backup operational readiness between outages, annual comprehensive backup service including oil change, filter replacement, and complete backup system inspection, biannual backup inspections for high-use backup generators or critical applications requiring enhanced backup reliability, and immediate backup service following extended operation during outages exceeding manufacturer-specified intervals.

Portable backup generator maintenance intervals include pre-season backup service before storm season ensuring backup operational readiness, post-season backup service preparing backup generators for storage with proper fuel treatment, annual comprehensive backup service regardless of usage maintaining all backup systems properly, and post-use backup service following extended backup operation during outages or work applications.

Our backup maintenance scheduling expertise helps property owners establish appropriate backup service intervals that maintain backup reliability while meeting manufacturer requirements for warranty coverage.

Backup Generator Warranty Maintenance Requirements

Backup generator warranties typically require documented backup maintenance performed according to manufacturer specifications to remain valid. Professional backup service ensures maintenance meets backup warranty requirements while providing documentation for potential backup claims.

Backup warranty maintenance requirements include manufacturer-specified backup service intervals that must be followed for warranty validity, approved replacement parts that meet manufacturer specifications for warranted backup repairs, documented backup service records that demonstrate proper maintenance history for backup warranty claims, and authorized backup service procedures that follow manufacturer protocols for specific backup generator models.

Backup documentation practices include detailed backup service records documenting all maintenance performed with dates and procedures, backup parts documentation recording replacement components used during service, backup test results documenting electrical output, battery condition, and backup system function, and backup maintenance recommendations identifying potential issues and suggested future backup service needs.

Our warranty-compliant backup service ensures backup generators receive proper maintenance that maintains manufacturer warranty coverage while providing documentation needed for potential backup claims.

Backup Generator Troubleshooting and Diagnostic Services

Backup generator problems require professional diagnosis to identify underlying backup issues and implement effective repairs that restore reliable backup power capability. Our backup troubleshooting services address backup generator failures while identifying root causes that prevent recurring backup problems.

Common backup generator problems include backup starting failures from battery, fuel system, or ignition issues preventing backup engine operation, backup running problems including rough operation, stalling, or failure to maintain proper speed, backup output problems with incorrect voltage, frequency, or inadequate backup power capacity, and backup control system failures affecting automatic start, backup transfer switch operation, or fault monitoring.

Backup diagnostic capabilities include backup engine diagnostics that identify mechanical, fuel, or ignition system problems, backup electrical diagnostics that assess output quality, regulation, and backup control system function, backup fuel system diagnostics that evaluate fuel delivery, carburetion, and contamination issues, and backup control system diagnostics that test automatic functions, sensors, and backup safety circuits.

Our backup diagnostic expertise ensures accurate backup problem identification and effective repairs that restore reliable backup generator operation while addressing underlying causes rather than just symptoms.

Backup Generator Repair Services

Backup generator repairs restore proper function following component failures or damage that affects backup power reliability. Professional backup repairs ensure backup generators return to service safely with proper function verified through comprehensive backup testing.

Common backup generator repairs include carburetor rebuilding or replacement that restores proper fuel delivery for gasoline backup engines, backup ignition system repairs including coil, module, and spark plug replacement, backup voltage regulator repairs that restore proper output voltage control and stability, backup starter motor repairs that restore reliable electric starting function, and backup control board repairs or replacement that restore automatic backup operation and monitoring capabilities.

Backup repair quality assurance includes quality replacement parts that meet or exceed original backup equipment specifications, proper backup repair procedures following manufacturer service guidelines, comprehensive backup testing that verifies proper function following repairs, and warranty coverage on backup repair work providing confidence in service quality.

Our backup repair expertise restores backup generator reliability while ensuring repairs meet manufacturer specifications and provide lasting solutions to backup power problems.

Emergency Backup Generator Service

Backup generator emergencies require prompt professional response when backup power systems fail during outages or critical situations. Our emergency backup service addresses urgent backup generator problems that cannot wait for scheduled backup maintenance appointments.

Emergency backup service situations include backup generator failures during active power outages when backup power is critically needed, post-storm backup service when widespread outages require rapid backup generator deployment, medical necessity situations when backup generator power supports life-safety equipment, and commercial emergencies when business operations depend on immediate backup power restoration.

Emergency backup response capabilities include rapid response that minimizes time without backup power during critical situations, field-serviceable backup repairs that restore operation without requiring shop service when possible, temporary backup solutions that provide interim power while comprehensive backup repairs are arranged, and priority scheduling that addresses urgent backup situations ahead of routine backup maintenance appointments.

Our emergency backup service provides responsive support when backup generator problems create urgent situations requiring immediate professional attention.

Planning Your Backup Generator Maintenance Investment

Backup generator maintenance represents a valuable investment in backup power reliability, backup equipment longevity, and family safety, requiring proper planning to ensure optimal backup service intervals and comprehensive care for your specific backup equipment. Our backup consultation process includes comprehensive assessment of your backup generator type, age, and maintenance history, detailed explanation of recommended backup service procedures and appropriate backup maintenance intervals, transparent pricing that includes all aspects of backup maintenance and identifies potential backup repair needs, and realistic expectations about backup maintenance benefits and backup generator lifespan considerations.

We work with homeowners to develop backup maintenance programs that match specific backup generator requirements, usage patterns, and backup reliability needs while ensuring backup power systems operate dependably when needed. Whether you need annual standby backup generator service, seasonal portable backup generator maintenance, or comprehensive backup system inspections for aging backup equipment, we provide the expertise and support that ensures your backup generator maintenance investment provides maximum backup reliability and equipment protection.

Long-Term Value of Professional Backup Generator Maintenance

Professional backup generator maintenance provides benefits that extend far beyond basic backup equipment upkeep. Properly maintained backup generators provide reliable backup power through verified backup operational readiness when outages occur, extended backup equipment lifespan through proper care that prevents premature wear and failure, reduced backup repair costs through early problem identification before minor backup issues become major failures, maintained warranty coverage through documented backup service meeting manufacturer requirements, and peace of mind that comes from knowing your backup power system will perform when your family needs backup power most.

Our systematic approach to backup generator maintenance has provided reliable backup power systems throughout our service area, building the experience and reputation that makes us the trusted choice for property owners who want comprehensive backup generator care and dependable emergency backup power. We understand that backup generator maintenance is an investment in family safety and emergency preparedness, which is why we approach every backup service with the care and precision it deserves.

Areas We Serve

Service Areas

If you need electrical services or an electrician in Seattle, WA, or any of the locations listed, do not hesitate to give us a call today! Schedule an appointment and we will head to your city to diagnose your electrical needs.

King County

Seattle, WA

Bellevue, WA

Kirkland, WA

Mercer Island, WA

Kent, WA

Federal Way, WA

Burien, WA

Des Moines, WA

Tukwila, WA

Woodinville, WA

Redmond, WA

Cottage Lake, WA

Shoreline, WA

Renton, WA

Fairwood, WA

White Center, WA

SeaTac, WA

South Center, WA

Snohomish County

Bothell, WA

Everett, WA

Snohomish, WA

Edmonds, WA

Marysville, WA

Pierce County

Tacoma, WA

Puyallup, WA

Edgewood, WA

Auburn, WA

Sumner, WA

Fife, WA

Dash Point, WA

Monday Through Saturday:

6:00am to 6:00pm

Sunday:

6:00am to 12:00pm

Hours of Operation

Location

Schedule Your Backup Generator Maintenance Consultation

Don't let neglected backup maintenance leave your backup generator unreliable when your family needs backup power most. Trust JCS Electrical's expertise to evaluate your backup generator maintenance needs and provide professional backup service that ensures your backup power system operates dependably during emergencies.

📞 Call (425) 552-1502 📧 Email team@jcselectricalseattle.com

Service Hours: Monday – Saturday: 6:00 AM to 6:00 PM Sunday: 6:00 AM to 12:00 PM

Serving: Seattle, WA | Everett, WA Kirkland, WA | Marysville, WA Redmond, WA | Shoreline, WA Edmonds, WA | Bellevue, WA Bothell, WA | Snohomish, WA Mercer Island, WA | Woodinville, WA Cottage Lake, WA

Whether you own a whole-house backup generator requiring annual professional backup service, a portable backup generator needing seasonal maintenance before storm season, a commercial backup power system demanding scheduled preventive backup care, or an aging backup generator showing signs of wear that requires comprehensive backup inspection and repair, JCS Electrical delivers the precision and expertise that ensures your backup generator maintenance provides dependable backup power and reliable backup operation for years of secure emergency preparedness. Contact us today for your free backup consultation and discover why property owners throughout Snohomish and King Counties trust us for their most important backup generator service needs.

Our Customer Reviews

EXCELLENT

⭐⭐⭐⭐⭐

Based on 20 Reviews on Google

FAQs

-

Absolutely, JCS Electrical is a fully licensed electrician near me and insured for all electrical services, ensuring your property and our team are protected. Operating in Servicing Greater Seattle, King, Snohomish and Pierce Counties, we comply with local regulations and uphold the highest standards of professionalism. Our reputation for reliable electrical contractor services speaks for itself. Call us to verify our credentials or book a free consultation.

-

If the project calls for permits and inspections, then we will ensure compliance with local building codes. We can handle permits and arrange for inspections, as required by law.

-

We adhere to the safety standards of the National Electrical Code and use proper equipment to prevent hazards like electrical fires or shocks.

-

Absolutely. We will be more than happy to assist in an urgent situation where a repair is necessary or provide post-project support when it is deemed fit. Our availability for emergencies is around the clock so please let us know if you are experiencing one.

Our electricians provide rapid response for urgent electrical issues, such as power outages or unsafe wiring, in Servicing Greater Seattle, King, Snohomish and Pierce Counties. Our licensed electricians ensure quick, safe solutions. Call us for emergency electrical service.

-

JCS Electrical, a leading electrician near me, provides top-quality electrical services for residential and commercial clients in Greater Seattle, Pierce, King and Snohomish Counties. Our services include home standby backup generator installations, EV charger installations, generator plug-in/interlock kits, main panel and subpanel installations, residential electrical wiring, electrical repairs, hot tub electrical installation, home automation (IoT), HVAC wiring, and specialty installations like heated floors, bathroom fans, and timer switches. We also offer outdoor electrical services such as landscape lighting, outdoor outlet installation, gate motors, and pool pump wiring, plus kitchen, bathroom, dining room, living room, and bedroom electrical upgrades. Our licensed electricians ensure reliable, code-compliant solutions. Call us for a free quote to start your project.

-

Routine maintenance ensures:

Reliable operation during power outages

Extended generator lifespan

Fuel efficiency

Early detection of potential failures

Compliance with manufacturer warranty requirements

-

Basic tasks like visual inspections can be done by owners, but professional service is recommended for oil changes, electrical testing, load testing, and control system diagnostics to ensure safety and reliability.

-

Lack of maintenance can lead to:

Failure during outages

Battery or starter failure

Fuel system issues

Overheating

Voided manufacturer warranties

-

Most manufacturers recommend annual servicing or after a specific number of run hours. Generators used frequently or in harsh environments may require more frequent maintenance.

-

Yes. Many manufacturers require documented professional maintenance at specified intervals to maintain warranty coverage.