Get Professional Electric Heat Pump Installation

in Seattle, Everett, Kirkland, Marysville, Redmond,

Edmonds, Bellevue, Snohomish, Shoreline,

Bothell, Mercer Island, Woodinville or Cottage Lake

Ready for a licensed electrician to help you with proper

electrical wiring for your heat pump installation in

Seattle, Everett, Kirkland, Marysville, Redmond, Edmonds,

Bellevue, Snohomish, Shoreline, Bothell, Mercer Island, Woodinville or Cottage Lake?

Call us at (425)552-1502 or fill out the form below so we can schedule your appointment.

Schedule Appointment

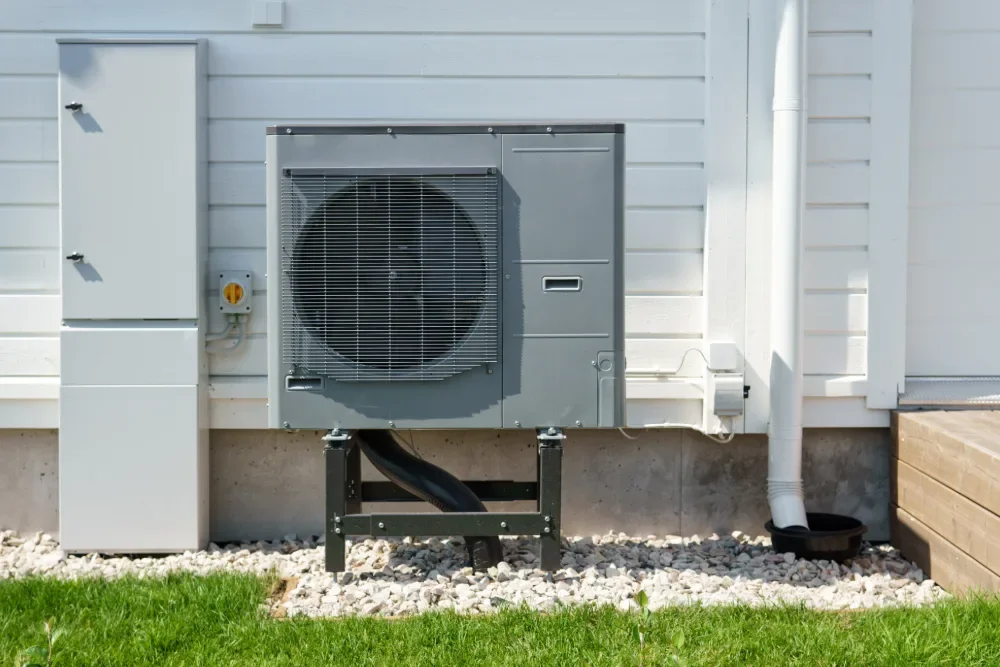

Expert Heat Pump Electrical Installation for Energy-Efficient Heating and Cooling Throughout Western Washington

Improperly installed heat pump electrical systems represent one of the most critical safety hazards and performance limitations that residential and commercial properties face, with the potential to cause electrical fires, compressor damage, and thousands of dollars in premature system failures from inadequate electrical supply or incorrect wiring connections. Whether you're installing new ductless mini-split heat pumps, upgrading to whole-house heat pump systems, adding heat pump electrical infrastructure that requires dedicated circuits and proper disconnect switches, or replacing outdated gas furnaces with modern electric heat pumps that demand substantial electrical connections, JCS Electrical delivers the comprehensive electrical expertise that has earned us five-star Google reviews and the trust of more than 100 property owners throughout Snohomish and King Counties.

Call (425) 552-1502 for professional heat pump electrical installation anywhere in our service area.

When Your Heat Pump Needs Professional Electrical Installation

Identifying the need for professional electric floor heating installation often becomes apparent during bathroom or kitchen renovation planning, but there are clear indicators that suggest your property would benefit significantly from expert electrical installation services. Existing electrical infrastructure in many properties requires careful assessment for radiant heating integration, especially homes with limited electrical panel capacity or insufficient circuit availability that make electrical evaluation and potential upgrades essential for successful floor heating system operation.

Critical electrical needs make professional floor heating installation essential including bathroom renovations that require GFCI-protected circuits for safe radiant heating operation in wet environments, kitchen remodels that demand dedicated circuits for floor heating mats beneath tile or stone flooring, master suite additions that need comprehensive electrical planning for luxurious floor warming systems, and whole-home radiant heating installations that require substantial electrical capacity and multiple dedicated circuits for optimal comfort throughout the property.

The safety impact of improper floor heating wiring becomes obvious when considering potential risks including electrical fires from inadequate circuit protection or improper heating mat connections that can cause catastrophic property damage, GFCI protection failures in bathrooms that create electrical shock hazards in wet environments, heating mat damage from incorrect voltage supply or circuit overloads that void warranties and create expensive replacement costs, and code violations when floor heating installations don't meet National Electrical Code requirements for fixed electric heating equipment in wet and dry locations.

Many property owners assume floor heating systems can connect to existing electrical circuits, but electric radiant heating requires specialized electrical infrastructure including dedicated circuits that provide adequate capacity for heating mat loads without affecting other electrical devices, GFCI protection in bathrooms that ensures electrical safety in high-moisture environments, proper thermostat wiring that enables accurate temperature control and prevents floor overheating, and while basic circuits may seem adequate, electric floor heating cannot operate safely or efficiently without proper electrical capacity and professional installation methods.

Understanding Heat Pump Electrical System Requirements

Modern heat pump electrical systems represent the most comprehensive HVAC infrastructure solution, providing reliable heating and cooling through proper electrical supply that ensures safe equipment function via correctly sized circuits and professional installation techniques. These professionally installed systems connect to dedicated electrical circuits and operate with proper control wiring that provides efficient temperature management and electrical safety throughout heating and cooling cycles.

Standard electrical circuits create capacity and reliability limitations but may seem adequate during initial planning, have insufficient electrical capacity that prevents proper heat pump compressor operation and defrost cycles, lack proper disconnect requirements that create code violations and safety concerns, and cannot support advanced heat pump features like smart thermostats, zoning controls, or auxiliary heat strips that require comprehensive electrical infrastructure.

Heat pump wiring requirements depend on your specific equipment type and system complexity including central ducted heat pumps that require dedicated 240-volt circuits for compressor and air handler components, ductless mini-split systems that demand properly sized circuits for each outdoor condenser and indoor air handler, multi-zone systems that require multiple circuits with appropriate breaker sizing for each zone, and dual-fuel hybrid systems that need proper electrical infrastructure to coordinate heat pump and backup heating operation.

Our Comprehensive Heat Pump Electrical Installation Strategy

Effective heat pump electrical installation requires detailed electrical load analysis and precise installation that ensures safe, reliable operation throughout your HVAC electrical system. Our approach begins with comprehensive heat pump electrical assessment including review of equipment specifications and electrical requirements from manufacturer documentation, evaluation of existing electrical panel capacity and available circuit slots for heat pump installation, assessment of electrical pathways and disconnect placement requirements for code compliance, and development of electrical solutions that provide reliable heat pump operation within electrical safety standards and building code requirements.

The installation process involves implementing properly sized dedicated circuits that safely supply power to heat pump equipment, while installing disconnect switches and grounding connections through code-compliant methods that ensure safe operation and provide consistent heating and cooling without creating electrical hazards or equipment reliability issues.

We install only high-quality electrical components throughout the process including properly rated electrical circuits and breakers that provide adequate capacity for heat pump compressor loads, code-compliant disconnect switches that enable safe service and meet electrical requirements, correct wire sizing that handles compressor startup currents and sustained high-amperage operation safely, and professional electrical connections that ensure safe heat pump operation and electrical code compliance throughout the installation.

We understand that heat pump electrical systems involve substantial power requirements and specific installation techniques that many property owners find technical, so we provide clear explanations of how electrical infrastructure supports HVAC equipment to provide safe, efficient heating and cooling throughout your property.

Modern Heat Pump Electrical Systems and Advanced Control Features

Electrical installations designed for modern heat pumps provide the most effective HVAC infrastructure for properties that require reliable heating and cooling with proper electrical capacity and advanced control capabilities. These systems can accommodate various heat pump technologies while providing consistent electrical supply that enables efficient operation and sophisticated temperature management.

Modern heat pump electrical systems include features that provide superior climate control reliability including dedicated circuit installations that prevent electrical interference with sensitive heat pump electronics, proper control wiring that enables smart thermostat operation and advanced efficiency features, Wi-Fi connectivity support that enables remote monitoring and temperature adjustment from smartphones and tablets, and appropriate disconnect switches that meet code requirements and enable safe equipment service.

Professional installation ensures these systems operate effectively including proper circuit protection that provides reliable overcurrent protection for heat pump compressor equipment, adequate wire sizing that handles compressor startup current and sustained operation safely, appropriate disconnect placement that meets code clearance requirements and enables safe service access, and code-compliant installation that meets all National Electrical Code requirements for HVAC heating and cooling equipment.

Modern heat pump electrical systems provide particular value for properties with specific climate control needs like high-efficiency variable-speed heat pumps that require dedicated circuits and proper electrical capacity for inverter-driven compressors, whole-house ducted systems that demand substantial electrical infrastructure for comprehensive heating and cooling, smart-enabled heat pumps that need network integration and advanced monitoring capabilities, and solar-ready installations that require electrical infrastructure for future renewable energy integration and net-zero home goals.

Electrical Load Analysis and Circuit Sizing for Heat Pump Equipment

Proper heat pump circuit sizing requires detailed electrical load analysis and accurate capacity calculations to ensure adequate electrical supply while accommodating high startup currents that compressor motors demand. Our load analysis process includes assessment of compressor wattage and amperage requirements including locked rotor amperage for startup conditions, evaluation of auxiliary heat strip electrical demands during extreme cold weather operation, analysis of air handler and indoor unit requirements for complete system electrical planning, and calculation of total heat pump electrical requirements that determine proper circuit sizing and electrical panel capacity.

Critical electrical considerations include compressor amperage that determines circuit sizing and wire gauge requirements for outdoor units, voltage requirements that verify proper 240-volt circuit configuration for most heat pump systems, minimum circuit ampacity and maximum overcurrent protection ratings specified by manufacturers, and control circuit wiring that enables proper thermostat operation and advanced smart home integration features.

Advanced heat pump features allow modern systems to operate efficiently including variable-speed inverter technology that adjusts compressor output for optimal efficiency and comfort, smart connectivity that provides remote control and energy monitoring capabilities through smartphone apps, demand response compatibility that enables utility load management and potential cost savings through time-of-use rate optimization, and cold-climate heat pump technology that maintains heating efficiency in sub-freezing temperatures.

Our heat pump electrical expertise ensures your installation provides adequate circuit capacity and proper electrical supply for reliable heating and cooling operation while maintaining electrical safety and supporting efficient climate control throughout your property.

Electrical Code Compliance and Safety Requirements for Heat Pump Installation

Heat pump electrical installations must comply with National Electrical Code requirements and electrical safety standards that govern HVAC equipment installation, disconnect requirements, and circuit protection. Code compliance ensures safe operation and prevents electrical hazards from improper heat pump wiring.

Electrical installation requirements include dedicated circuits that provide adequate capacity for heat pump equipment without sharing with other electrical loads, proper disconnect switches within sight of outdoor units that meet accessibility and clearance requirements for safe service access, correct grounding and bonding that provides electrical safety throughout the heat pump system, and appropriate circuit protection using manufacturer-specified breaker sizes that ensure safe operation during compressor startup and sustained use.

Safety considerations include adequate working clearances that enable safe heat pump equipment service and maintenance around indoor and outdoor components, proper disconnect placement that maintains required distances and line-of-sight accessibility from equipment, appropriate wire sizing that prevents overheating during compressor startup and sustained high-amperage operation, and correct installation techniques that follow manufacturer specifications and electrical code requirements for HVAC systems.

Our heat pump electrical expertise ensures installations meet all applicable NEC requirements while following manufacturer guidelines and industry best practices for reliable, safe HVAC system operation throughout the equipment lifespan.

Ductless Mini-Split Heat Pump Electrical Requirements and Installation

Ductless mini-split heat pumps present unique electrical opportunities that require specialized expertise and proper electrical infrastructure to provide efficient zone-controlled heating and cooling throughout your property. These versatile systems require comprehensive electrical planning and professional installation to operate safely and effectively while maximizing energy efficiency benefits.

Ductless mini-split electrical considerations include dedicated circuit requirements for each outdoor condenser unit based on manufacturer specifications, proper wire sizing that handles compressor startup currents without voltage drop that affects performance, outdoor disconnect switch installation within sight of each condenser for safe service access, and low-voltage control wiring between indoor and outdoor units that enables proper communication and operation.

Installation requirements for mini-split systems include assessment of existing electrical panel capacity and available breaker slots for new circuits, calculation of total amperage requirements based on outdoor unit specifications and number of indoor heads, installation of dedicated circuits with appropriate breaker sizing for each system, and proper wire routing that maintains code-compliant clearances and protects wiring from physical damage and weather exposure.

Ductless mini-split electrical installations provide benefits including zone-controlled heating and cooling that eliminates energy waste from conditioning unoccupied spaces, high efficiency ratings that reduce electrical consumption compared to conventional HVAC systems, quiet operation from modern inverter-driven compressors that vary speed for optimal comfort, and flexible installation options that enable heating and cooling in spaces without existing ductwork.

Whole-House Ducted Heat Pump Electrical Installation and Efficiency Benefits

Whole-house ducted heat pumps represent the most comprehensive electric heating and cooling solution available, using heat pump technology to provide efficient climate control through existing ductwork while consuming significantly less electricity than conventional resistance heating or separate heating and cooling systems. These advanced systems require proper electrical installation to maximize efficiency benefits and ensure reliable year-round operation.

Whole-house heat pump electrical requirements include dedicated 240-volt circuits that provide adequate capacity for compressor operation and air handler electrical demands, proper circuit sizing that accommodates both compressor startup currents and sustained operation during extreme temperatures, appropriate disconnect installation near outdoor equipment that enables safe service and meets code requirements, and control wiring that supports smart thermostat integration and zoning system capabilities.

Efficiency advantages of ducted heat pumps include energy consumption reductions of 50-70% compared to conventional electric resistance heating, lower operating costs that provide significant savings over equipment lifespan compared to gas furnaces and air conditioners, reduced environmental impact through decreased electricity consumption and elimination of on-site fossil fuel combustion, and utility rebate eligibility that may offset initial installation costs through energy efficiency incentive programs.

Our whole-house heat pump electrical expertise ensures proper installation that maximizes efficiency benefits while providing reliable heating and cooling through auxiliary heat capability when outdoor temperatures limit heat pump performance.

Cold-Climate Heat Pump Electrical Requirements and Considerations

Cold-climate heat pumps represent advanced HVAC technology designed specifically for Pacific Northwest weather conditions, maintaining heating efficiency in temperatures well below freezing where conventional heat pumps lose effectiveness. These specialized systems require proper electrical installation to deliver reliable heating performance throughout Washington's coldest winter days.

Cold-climate heat pump electrical considerations include higher amperage requirements than standard heat pumps due to enhanced compressor and defrost system capabilities, auxiliary electric heat strip circuits that provide backup heating during extreme cold or high heating demand periods, proper circuit sizing that accommodates both heat pump operation and auxiliary heat simultaneously, and advanced defrost cycle electrical demands that maintain outdoor coil efficiency in freezing conditions.

Installation requirements for cold-climate systems include assessment of total electrical load including heat pump and auxiliary heat operating simultaneously, potential electrical panel upgrades to accommodate substantial heating system electrical demands, proper disconnect installation and circuit protection for reliable cold-weather operation, and control wiring that enables intelligent switching between heat pump and auxiliary heating modes.

Cold-climate heat pump installations provide benefits for Western Washington properties including efficient heating operation in temperatures down to -15°F or lower with proper equipment selection, elimination of fossil fuel dependence for heating while maintaining comfort during coldest weather, reduced operating costs compared to electric resistance heating as primary heat source, and environmental benefits from all-electric heating that supports carbon reduction and electrification goals.

Gas-to-Electric Heat Pump Conversion Electrical Requirements

Converting from gas furnace heating to electric heat pump systems requires complete electrical infrastructure installation since existing gas furnace locations typically lack the dedicated circuits and electrical capacity that heat pump systems demand. These conversion projects require comprehensive electrical planning and professional installation to provide reliable year-round heating and cooling through new electrical infrastructure.

Conversion electrical requirements include new dedicated circuit installation from electrical panel to indoor and outdoor heat pump equipment locations, potential electrical panel upgrades to accommodate additional high-amperage circuits for compressor and auxiliary heat, proper wire routing through walls and ceilings to reach equipment placement for both indoor and outdoor components, and disconnect switch installation that meets code requirements and enables safe service access for HVAC technicians.

Reasons for gas-to-electric heat pump conversion include elimination of gas line safety concerns and potential carbon monoxide risks from combustion heating equipment, preparation for electrification goals and reduced fossil fuel dependence aligned with Washington State energy policies, compatibility with solar panel installations and renewable energy systems for net-zero home operation, and access to high-efficiency heat pump technology that provides both heating and cooling from single system with substantial energy savings.

Our conversion expertise ensures proper electrical infrastructure installation that supports reliable heat pump operation while meeting all code requirements and providing safe, efficient heating and cooling throughout your property for years of comfortable operation.

Multi-Zone Heat Pump System Electrical Planning

Multi-zone heat pump systems provide customized climate control throughout properties with varying heating and cooling needs, requiring comprehensive electrical planning to support multiple indoor units and zone control capabilities. These sophisticated systems demand proper electrical infrastructure to enable independent temperature management in different areas while maintaining electrical safety and system reliability.

Multi-zone electrical considerations include circuit requirements for outdoor condenser units sized to support multiple indoor heads, proper electrical capacity for simultaneous operation of all zones during peak demand conditions, low-voltage control wiring that enables communication between outdoor unit and multiple indoor air handlers, and potential branch circuit requirements for larger indoor units or systems with electric backup heat in each zone.

Installation requirements for multi-zone systems include comprehensive load analysis for total system electrical demand across all zones, appropriate circuit sizing based on maximum simultaneous operation scenarios, proper wire routing to multiple indoor unit locations throughout the property, and disconnect and circuit protection installation that meets code requirements for complex multi-component systems.

Multi-zone heat pump electrical installations provide benefits including individualized temperature control that eliminates conflicts over thermostat settings in different areas, energy efficiency from heating or cooling only occupied zones rather than entire properties, quiet operation with indoor units sized appropriately for each space, and flexible expansion capability that allows adding zones as needs change.

Planning Your Heat Pump Electrical Installation Investment

Heat pump electrical installation represents a valuable investment in property comfort, energy efficiency, and long-term operating cost savings, requiring proper evaluation and planning to ensure optimal electrical infrastructure and equipment compatibility. Our consultation process includes comprehensive assessment of your heat pump electrical requirements and system specifications, detailed explanation of different installation options and electrical upgrade needs, transparent pricing that includes all aspects of installation and any required electrical modifications, and realistic expectations about system operation, energy efficiency, and seasonal performance.

We work with homeowners, HVAC contractors, and builders to develop electrical solutions that match specific heating and cooling requirements, existing electrical infrastructure characteristics, and efficiency goals while ensuring all electrical circuits operate safely and reliably together. Whether you need basic mini-split circuit installation or comprehensive electrical infrastructure for whole-house cold-climate heat pump systems with auxiliary heat, we provide the expertise and support that ensures your heat pump electrical investment provides maximum reliability, efficiency, and long-term performance.

Long-Term Value of Professional Heat Pump Electrical Installation

Professional heat pump electrical installation provides benefits that extend far beyond basic equipment connectivity. Properly installed heat pump electrical systems provide reliable heating and cooling through adequate circuit capacity and correct connections, prevent equipment damage from proper electrical supply and circuit protection that maintains manufacturer warranty coverage, support energy efficiency through correct wiring that enables advanced heat pump features and smart controls, and provide peace of mind that comes from knowing your HVAC equipment operates safely with proper electrical infrastructure.

Our systematic approach to heat pump electrical installation has provided reliable HVAC electrical systems throughout our service area, building the experience and reputation that makes us the trusted choice for property owners who want comprehensive electrical safety and heat pump reliability. We understand that heat pump electrical installation is an investment in maintaining property comfort and ensuring efficient climate control operation, which is why we approach every project with the care and precision it deserves.

Areas We Serve

Service Areas

If you need electrical services or an electrician in Seattle, WA, or any of the locations listed, do not hesitate to give us a call today! Schedule an appointment and we will head to your city to diagnose your electrical needs.

King County

Seattle, WA

Bellevue, WA

Kirkland, WA

Mercer Island, WA

Kent, WA

Federal Way, WA

Burien, WA

Des Moines, WA

Tukwila, WA

Woodinville, WA

Redmond, WA

Cottage Lake, WA

Shoreline, WA

Renton, WA

Fairwood, WA

White Center, WA

SeaTac, WA

South Center, WA

Snohomish County

Bothell, WA

Everett, WA

Snohomish, WA

Edmonds, WA

Marysville, WA

Pierce County

Tacoma, WA

Puyallup, WA

Edgewood, WA

Auburn, WA

Sumner, WA

Fife, WA

Dash Point, WA

Monday Through Saturday:

6:00am to 6:00pm

Sunday:

6:00am to 12:00pm

Hours of Operation

Location

Schedule Your Heat Pump Electrical Installation Consultation

Don't let inadequate electrical infrastructure compromise your heating and cooling reliability when professional heat pump electrical installation could provide proper electrical capacity and safe equipment operation. Trust JCS Electrical's expertise to evaluate your heat pump electrical needs and provide professional installation solutions that ensure your HVAC equipment operates reliably with proper electrical support.

📞 Call (425) 552-1502 📧 Email team@jcselectricalseattle.com

Service Hours: Monday – Saturday: 6:00 AM to 6:00 PM Sunday: 6:00 AM to 12:00 PM

Serving: Seattle, WA | Everett, WA | Kirkland, WA | Marysville, WA | Redmond, WA | Shoreline, WA | Edmonds, WA | Bellevue, WA | Bothell, WA | Snohomish, WA | Mercer Island, WA | Woodinville, WA | Cottage Lake, WA

Whether you're installing new ductless mini-split heat pumps with proper electrical infrastructure, upgrading to energy-efficient whole-house ducted systems with adequate circuit capacity, or converting from gas furnace to electric heat pump with complete electrical installation, JCS Electrical delivers the precision and expertise that ensures your heat pump electrical installation provides dependable electrical support and reliable climate control for years of comfortable, energy-efficient operation. Contact us today for your free consultation and discover why property owners throughout Snohomish and King Counties trust us for their most important heat pump electrical installations.

Our Customer Reviews

EXCELLENT

⭐⭐⭐⭐⭐

Based on 20 Reviews on Google

FAQs

-

Absolutely, JCS Electrical is a fully licensed electrician near me and insured for all electrical services, ensuring your property and our team are protected. Operating in Servicing Greater Seattle, King, Snohomish and Pierce Counties, we comply with local regulations and uphold the highest standards of professionalism. Our reputation for reliable electrical contractor services speaks for itself. Call us to verify our credentials or book a free consultation.

-

If the project calls for permits and inspections, then we will ensure compliance with local building codes. We can handle permits and arrange for inspections, as required by law.

-

We adhere to the safety standards of the National Electrical Code and use proper equipment to prevent hazards like electrical fires or shocks.

-

Absolutely. We will be more than happy to assist in an urgent situation where a repair is necessary or provide post-project support when it is deemed fit. Our availability for emergencies is around the clock so please let us know if you are experiencing one.

Our electricians provide rapid response for urgent electrical issues, such as power outages or unsafe wiring, in Servicing Greater Seattle, King, Snohomish and Pierce Counties. Our licensed electricians ensure quick, safe solutions. Call us for emergency electrical service.

-

JCS Electrical, a leading electrician near me, provides top-quality electrical services for residential and commercial clients in Greater Seattle, Pierce, King and Snohomish Counties. Our services include home standby backup generator installations, EV charger installations, generator plug-in/interlock kits, main panel and subpanel installations, residential electrical wiring, electrical repairs, hot tub electrical installation, home automation (IoT), HVAC wiring, and specialty installations like heated floors, bathroom fans, and timer switches. We also offer outdoor electrical services such as landscape lighting, outdoor outlet installation, gate motors, and pool pump wiring, plus kitchen, bathroom, dining room, living room, and bedroom electrical upgrades. Our licensed electricians ensure reliable, code-compliant solutions. Call us for a free quote to start your project.

-

A heat pump is an energy-efficient system that heats and cools your home by transferring heat rather than generating it. It extracts heat from the air or ground and moves it indoors for heating or outdoors for cooling.

-

Common types include:

Air-source heat pumps (most common)

Ductless mini-split heat pumps

Ground-source (geothermal) heat pumps

Hybrid or dual-fuel systems

-

Most homes are suitable. Factors considered include:

Home size and insulation

Existing ductwork (if any)

Electrical panel capacity

Climate conditions

A professional site assessment confirms compatibility.

-

Yes. Modern cold-climate heat pumps operate efficiently even in freezing temperatures. In very cold regions, a backup heat source may be recommended.

-

Maintenance includes:

Cleaning or replacing air filters

Clearing outdoor units of debris

Annual professional inspections

Routine maintenance ensures optimal performance and longevity.